A sustainable and totally circular exhibition space. At Cersaie 2023, for the first time, Iris Ceramica Group together with Henoto designed a booth in which every single element was designed to be 100 percent reusable.

Zero Waste

The stand was designed according to the principles of Industry 4.0, which allowed us to optimize processes, taking advantage of automation and high digitization. The project involved the close cooperation of the marketing and R&D departments of both companies.

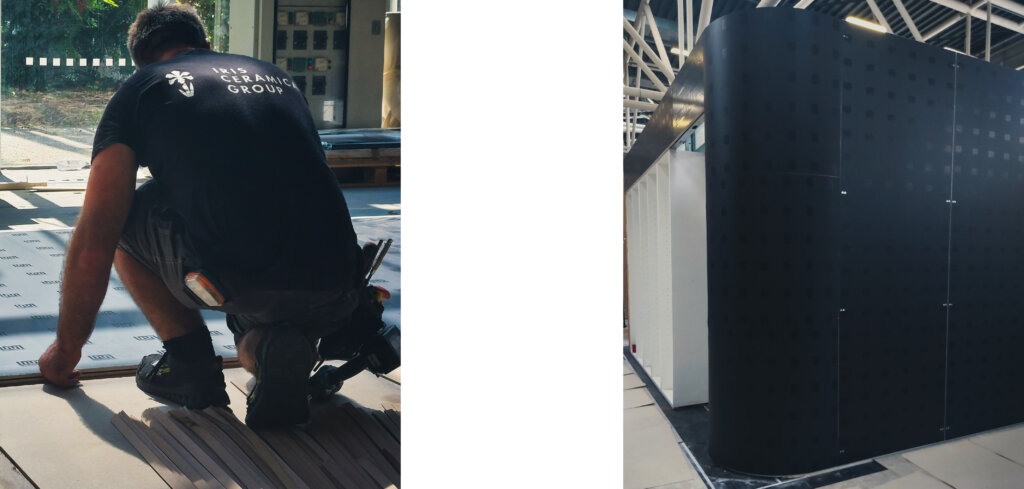

Material selection was key, ensuring assembly and disassembly without generating waste and with a significant downsizing of the volumes of materials to be transported. The elimination of steps such as painting and cutting in place, along with the use of light but strong materials such asaluminum and fabric, has significantly improved the working conditions of the professionals on site, all while maintaining a high standard of quality and a prominent aesthetic impact.

Attract System

Iris' entrepreneurial vision for this project was clear: to re-engineer ceramics to improve human-environment interaction, in line with Henoto's philosophy "The Neutral Way philosophy”.

In fact, the Iris Group presented the revolutionary "Attract" system: a system that enables the magnetic assembly of slabs ceramic tiles quickly and without the need to use adhesives. This means that each slab can be removed or replaced without requiring demolition, opening the way to unlimited reuse of both the slabs themselves and the magnetic base. This vision has come to life in the Planet-Friendly, exhibition space, created without waste of materials.

Both the walls and the platform have been equipped with a magnetic film that allows the ceramic slabs to be easily laid and removed using the "Attract" system. The ceiling, on the other hand, was designed with the patented CoverUp EVO technology from Henoto, consisting of an extruded aluminum profile to which is applied a highly flexible and mechanically resistant fabric, ensuring high quality and remarkable aesthetic impact.

The use of Cover Up technology has made it possible to optimize transportation, completely eliminating on-site painting and lacquering processes. In addition, the fabric parts, being fully washable, can be reused for future projects helping to reduce waste even further.